Cobble Stone Maker Yellow Granite

A cobble stone maker is a machine or device that is used to create cobblestones from raw materials such as stone or concrete. These machines can be used in a variety of settings, including residential and commercial projects, as well as in the construction of roads, sidewalks, and other types of paving.

There are several different types of cobblestone makers available on the market, ranging from small, hand-held models to larger, more industrial-sized machines. Some cobblestone makers use molds to create the desired shape and size of the cobblestones, while others use a process called “paver forming” to create the cobblestones by pressing the raw materials into shape.

One of the benefits of using a cobblestone maker is that it allows for a high level of customization in the final product. Cobblestone makers can create cobblestones in a variety of shapes, sizes, and colors, depending on the specific needs and preferences of the user. This can be especially useful for projects that require a specific aesthetic or design, such as historic renovations or the creation of themed walkways.

Cobblestone makers also offer a number of other advantages. For one, they can help to reduce the amount of waste generated during the construction process, as the raw materials can be carefully measured and used to create the exact number of cobblestones needed for a project. Additionally, cobblestone makers can help to speed up the construction process, as they can produce large quantities of cobblestones in a relatively short amount of time.

Overall, cobblestone makers are a useful tool for anyone involved in the construction or paving industry. Whether you are working on a small residential project or a large commercial project, a cobblestone maker can help you to create high-quality cobblestones that meet your specific needs and preferences. So, it is a very important machine in the construction industry.

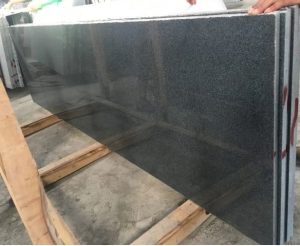

| Product name: | Various granite paving stone |

| Material: | G562 Granite, G603 Granite, G654 Granite, G682, etc. |

|

Size: |

Sizes 5X5X5CM,8X8X8CM,9X9X9CM,10X10X10CM,10x10x5cm,10x20x5cm,9.5×9.5x4CM,19.5×19.5x4CM,22X11X5CM,16.5X11.5X5CM,19.7X19.7X8CM,14.5X14.5X8CM,16X16X16CM, 22X16X16CM,27x18x9cm,18x18x9cm,18x18x18CM or Customized |

| Customized specifications are available | |

| Thickness tolerance: | ±1mm,±1.5mm,±2mm,as per client’s quality requirement |

|

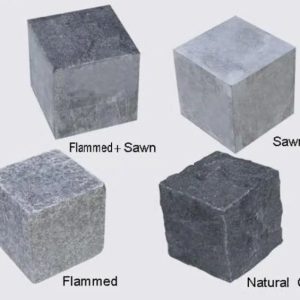

Surface: |

Finishing a. All sides natural split b. All sides sawn cut c. 5 sides saw cut, Surface natural split d. 5 sides saw cut, Surface flamed e. 4 sides saw cut, top natural split, tumbled ,mesh back |

| Packing: | Seaworthy wooden bundles and wooden crates |

| Application: | Widely used for Interior and Exterior decoration |

| Delivery time: | 15-20 days for regular sizes |

|

Certificate: |

CE,SGS |

|

Payment terms: |

T/T,L/C,D/P |

| Advantage: |

1) One-stop service for stone; 2) Own 3 quarries and 9 factories; 3) Design and technology support. |

| Quality and delivery assurance : |

During the whole production process, from material choosing, fabrication to package, our QC will strictly control each piece and every process to ensure quality standards and on time delivery. |