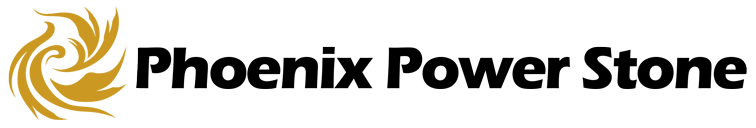

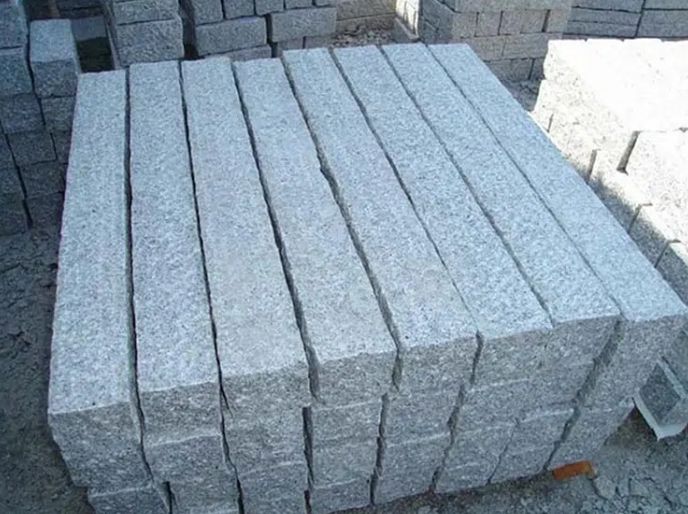

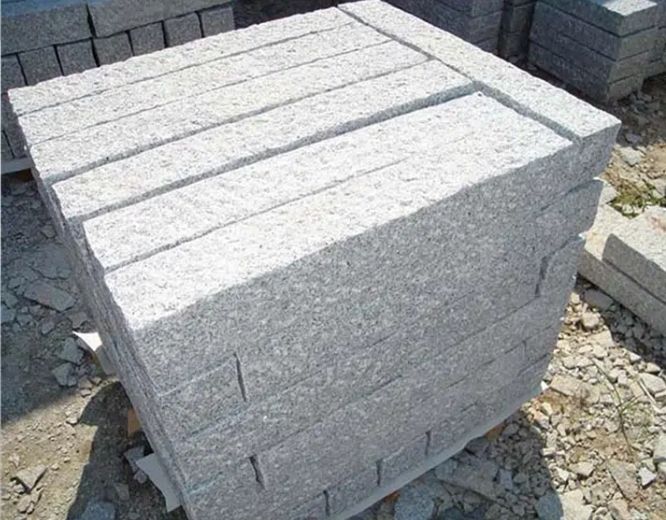

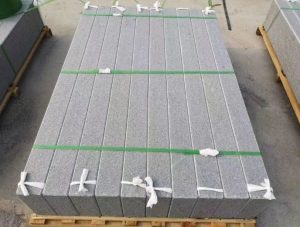

Granite Curbstone Manufacture China Landscaping G603

Granite curbstones are an essential component of modern urban landscapes. They serve as a barrier between the road and sidewalk, defining pedestrian walkways, and preventing vehicles from encroaching onto sidewalks. Granite is a popular choice for curbstone manufacture due to its durability, resistance to weathering, and aesthetic appeal. In this article, we will delve into the process of granite curbstone manufacture, from quarrying to installation.

Quarrying Granite curbstones are made from natural stone, which is quarried from mountainsides and hills. Quarrying involves drilling and blasting to extract large blocks of granite from the earth. These blocks can weigh several tons and are transported to the processing facility.

Cutting At the processing facility, the granite blocks are cut into smaller pieces using diamond saws. These saws have diamond-tipped blades that can cut through the tough granite with precision. The granite pieces are then shaped into the desired size and shape of the curbstone using specialized machines.

Finishing After the curbstone is cut and shaped, it is subjected to a finishing process that involves grinding and polishing. This process removes any rough edges and creates a smooth surface. The finishing process also enhances the natural color and texture of the granite, giving it a glossy and refined appearance.

Quality Control During the manufacturing process, each granite curbstone is carefully inspected for quality control. Any imperfections or defects are addressed to ensure that the final product meets the required standards of strength, durability, and appearance.

Installation The final step in the granite curbstone manufacturing process is installation. Curbstones are installed by trained professionals using specialized tools and equipment. The curbstone is set in a concrete foundation and securely anchored to the ground to prevent displacement.

In conclusion, granite curbstone manufacture involves a complex process that begins with quarrying and ends with installation. The durability and aesthetic appeal of granite make it a popular choice for curbstone manufacture. With proper maintenance, granite curbstones can last for decades, providing a functional and attractive addition to urban landscapes.

| Product name: | Various Granite |

| Material: | Granite |

| Color: | White,black,yellow,red,pink,gray,brown,blue,green,etc |

| Size: | Tiles available 12’x12″,24’x24″,12’x24″,etc 300x300mm,300x600mm,400x400mm,600x600mm,etc |

| Slabs available

180cmUpx60UP,180cmUpx65cmUP,180cmUpx70cmUP,etc |

|

| Customized specifications are available | |

| Thickness tolerance: | ±0.05mm,±1mm,±1.5mm,±2mm,as per client’s quality requirement |

| Surface: | Polished,honed,flamed,sandblasted,bushhammerred,antique,natural split,flamed and brushed,etc |

| Packing: | Seaworthy wooden pallets,wooden bundles and wooden crates |

| Application: | Floor,wall,pattern,countertop,interior decoration and exterior decoration |

| Delivery time: | 15-20 days for regular sizes |

| Certificate: | CE,SGS |

| Payment terms: | T/T,L/C,D/P |

| Advantage: | 1) One-stop service for stone;

2) own 3 quarries and 9 factories; 3) State of the art technology supports. |

| Quality and delivery assurance : | During the whole production process, from material choosing, fabrication to package, our QC will strictly control each piece and every process to ensure quality standards and on time delivery. |