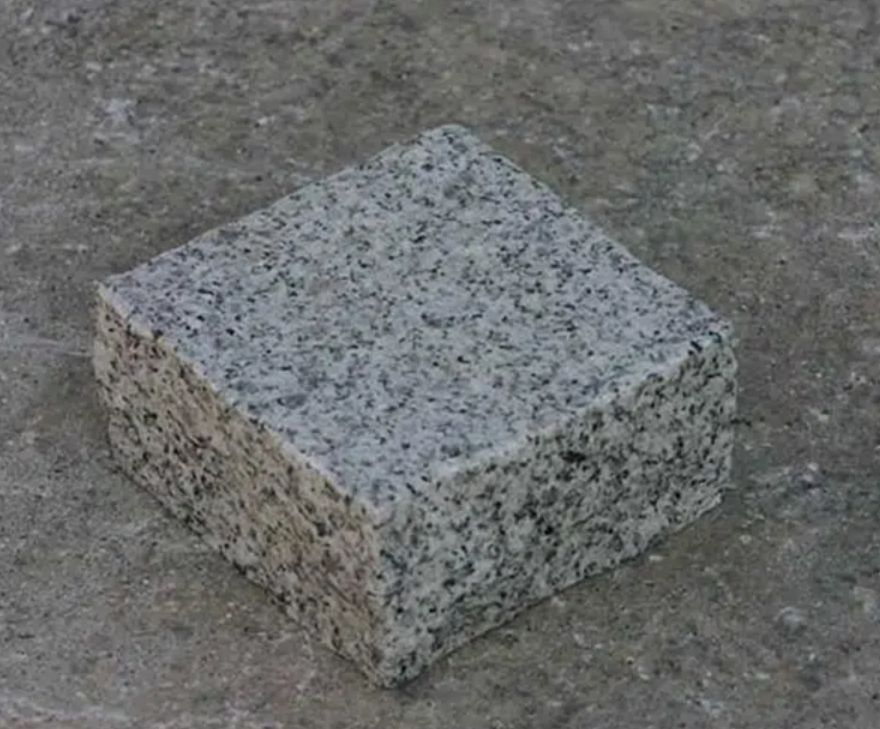

stone paving slabs factory cheap patio paver stones g603 grey granite

A stone paving slabs factory is a manufacturing facility that specializes in the production of stone paving slabs. These slabs are made from a variety of materials including granite, marble, and limestone, and are used for a variety of applications including driveways, patios, sidewalks, and flooring.

The process of making stone paving slabs begins with the selection of raw materials. The raw materials are typically mined from quarries and then transported to the factory where they are cut and shaped into slabs using specialized equipment such as saws and polishers.

Once the raw materials have been cut and shaped into slabs, they are inspected for quality and defects. Any defective slabs are removed from the production process and discarded. The remaining slabs are then transported to the finishing area where they are polished and finished to a high level of quality.

After the slabs have been finished, they are packaged and shipped to distributors or directly to customers. The stone paving slabs factory may also have a showroom or sales office where customers can view and purchase the finished products.

In addition to producing stone paving slabs, many stone paving slabs factories also offer custom fabrication services. This means that they can create custom-sized and shaped slabs to meet the specific needs of their customers.

The stone paving slabs industry is a competitive one, and factories must continuously strive to improve the quality of their products and reduce production costs in order to remain competitive. This may involve investing in new technology and equipment, implementing lean manufacturing processes, and training employees in the latest production techniques.

Overall, stone paving slabs factories play a vital role in the construction industry, providing a durable and attractive material that is used in a variety of applications.

| Product name: | Various granite paving stone |

| Material: | G562 Granite, G603 Granite, G654 Granite, G682, etc. |

|

Size: |

Sizes 5X5X5CM,8X8X8CM,9X9X9CM,10X10X10CM,10x10x5cm,10x20x5cm,9.5×9.5x4CM,19.5×19.5x4CM,22X11X5CM, 16.5X11.5X5CM,19.7X19.7X8CM,14.5X14.5X8CM,16X16X16CM, 22X16X16CM,27x18x9cm,18x18x9cm,18x18x18CM or Customized |

| Customized specifications are available | |

| Thickness tolerance: | ±1mm,±1.5mm,±2mm,as per client’s quality requirement |

|

Surface: |

Finishing a. All sides natural split b. All sides sawn cut c. 5 sides saw cut, Surface natural split d. 5 sides saw cut, Surface flamed e. 4 sides saw cut, top natural split, tumbled ,mesh back |

| Packing: | Seaworthy wooden bundles and wooden crates |

| Application: | Widely used for Interior and Exterior decoration |

| Delivery time: | 15-20 days for regular sizes |

|

Certificate: |

CE,SGS |

|

Payment terms: |

T/T,L/C,D/P |

| Advantage: |

1) One-stop service for stone; 2) Own 3 quarries and 9 factories; 3) Design and technology support. |

| Quality and delivery assurance : |

During the whole production process, from material choosing, fabrication to package, our QC will strictly control each piece and every process to ensure quality standards and on time delivery. |